In the global battle against African Swine Fever (ASF), the focus is often squarely on perimeter biosecurity: disinfecting trucks, sanitizing personnel, and controlling feed. While these are undeniably critical, a crucial frontline within the farm itself is frequently overlooked—the swine housing environment.

Poorly designed floors and pens can become silent accomplices to pathogen persistence and spread. They create micro-environments where moisture lingers, waste accumulates, and stress compromises animal immunity. This article shifts the perspective inward, arguing that modern slatted floors and intelligent pen design are not just infrastructure—they are active, first-line components of a comprehensive ASF defense strategy.

The choice of flooring material is a direct decision about your farm's long-term hygiene and biosecurity. Unlike generic options, a purpose-engineered floor addresses ASF risks at the source.

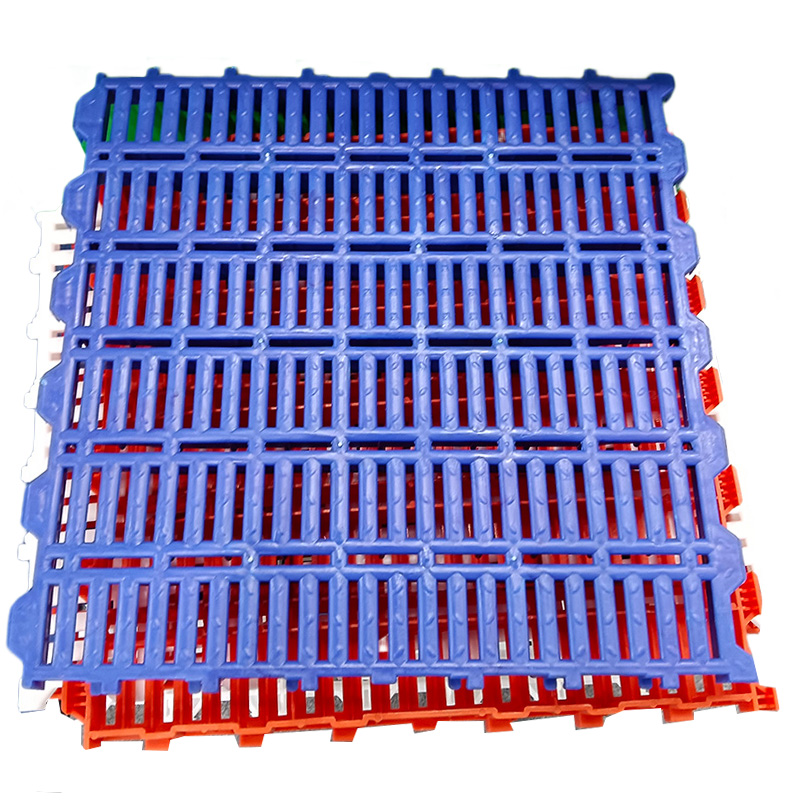

Plastic Slatted Floors (The Precision Hygienist):

As shown in our product image, this floor is engineered with a high-density grid of precision-molded drainage holes. This design is not random; it maximizes open area for immediate manure fall-through while providing a comfortable, slip-resistant resting surface. The smooth, non-absorbent plastic ensures waste and water have zero adhesion, enabling a complete, rapid flush-down and the fastest possible drying time of any material. This creates a consistently dry surface hostile to pathogen survival. Its lightweight nature allows for effortless installation and removal, making it the ideal choice for achieving a perfect, deep clean between batches in strict "all-in-all-out" systems.

Caption: Our plastic slatted floor's precision grid ensures rapid drainage and instant drying, leaving no moisture for pathogens.

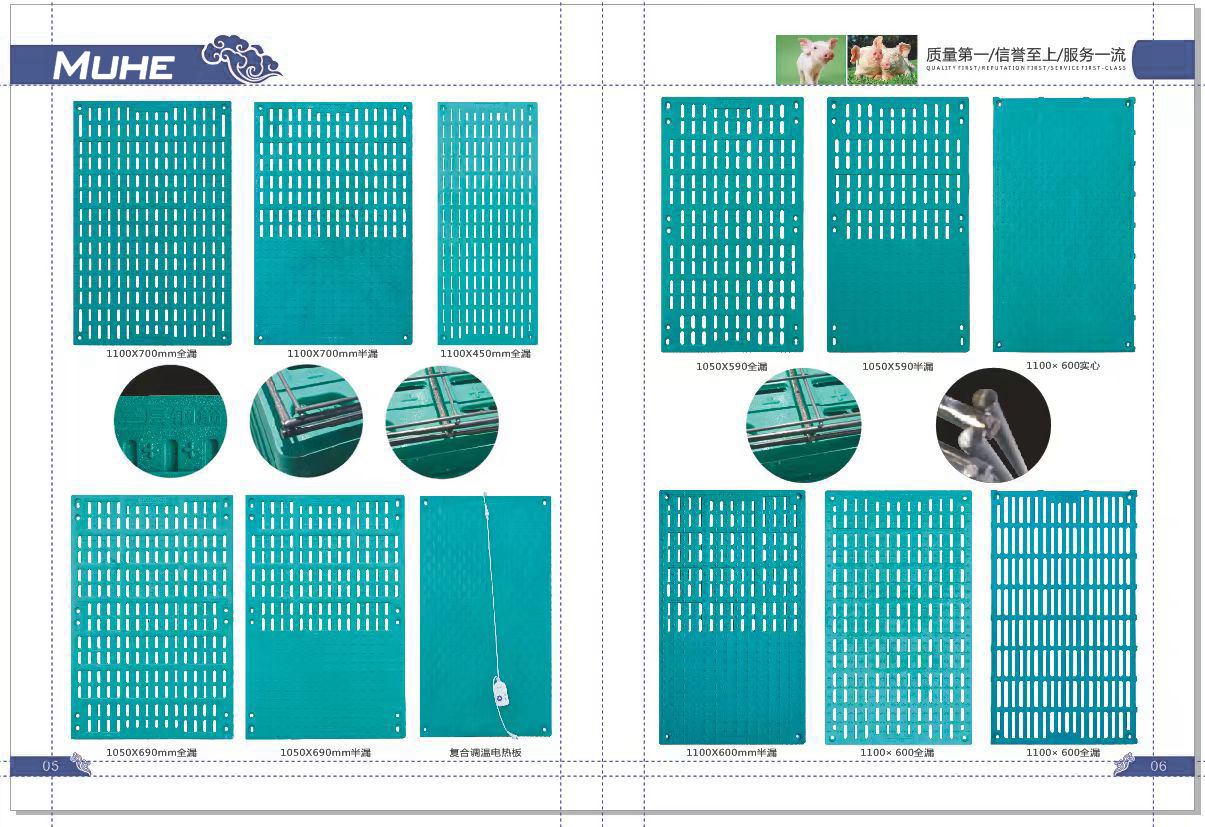

BMC (Bulk Molding Compound) Slatted Floors (The Durable Fortress):

Where ultimate durability and dimensional stability are paramount. BMC is a composite material that is completely impervious to moisture, corrosion, and wear. It maintains a flawless, monolithic surface for decades, withstanding high-pressure washing and harsh disinfectants without degradation. This permanent "no-crack" solution eliminates all potential microbial harborage sites.

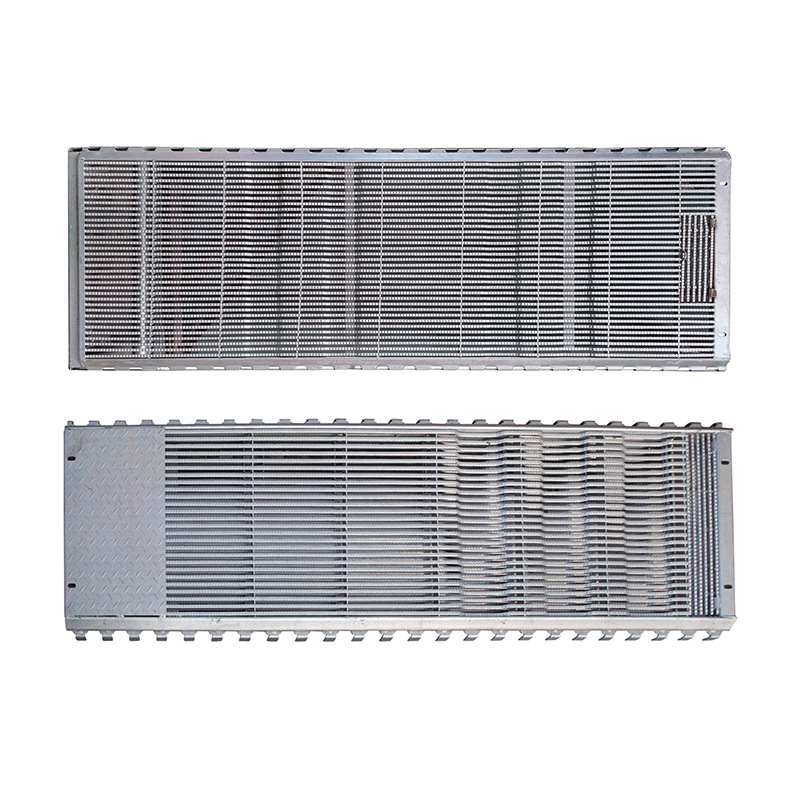

Triangular Steel Slatted Floors (The Heavy-Duty Workhorse):

Engineered for maximum strength in high-load areas. The unique inverted triangular profile provides exceptional structural support and creates a self-cleaning, wide-open gap. This design maximizes manure passage and air circulation underneath the pen, significantly promoting a drier overall microenvironment. When hot-dip galvanized, it provides long-lasting protection against rust.

Beyond material, it's the science of the design that delivers biosecurity. Whether it's the engineered hole pattern in our plastic floors, the solid durability of BMC, or the open structure of triangular steel, each is crafted to achieve one critical goal: creating a dry resting "zone" for animals. Combined with integrated slope designs, our floors ensure liquids are channeled away instantly. A dry floor is one of the most effective and underrated biosecurity tools—it directly reduces pathogen viability, cuts ammonia production, and enhances animal comfort and immunity.

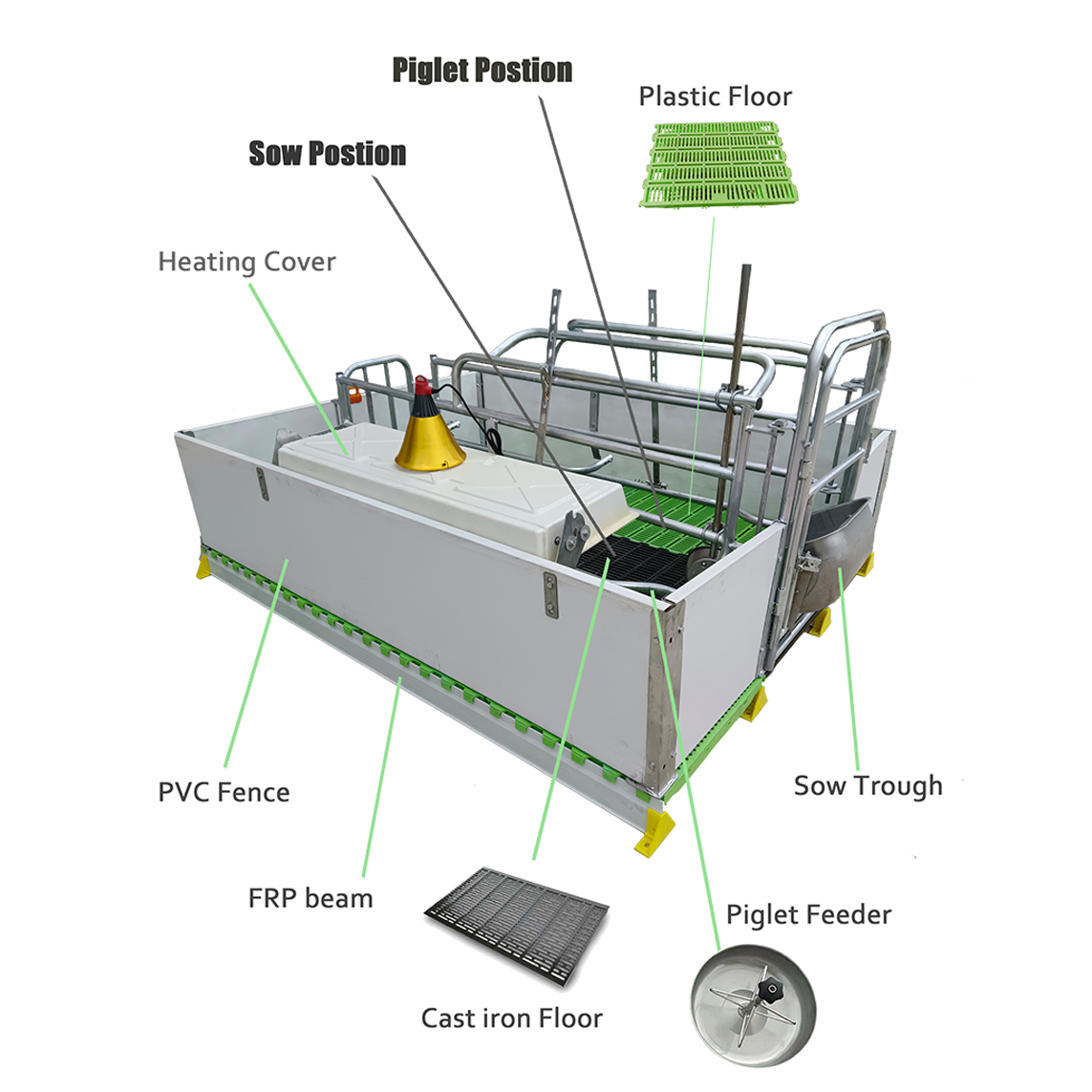

Advanced flooring must be paired with intelligent pen design to form a complete defensive system. Our farrowing crate, as detailed in the schematic below, is engineered from the ground up to support critical biosecurity protocols.

Schematic of our biosecurity-focused farrowing crate design: Zoned flooring, durable FRP/PVC materials, and integrated piglet heating work together to support a healthier, more manageable environment.

The crate is meticulously divided into dedicated zones for the sow and piglets. This is not merely for organization—it's a core biosecurity feature. The solid cast iron floor in the sow area provides secure, comfortable footing, while the plastic slatted floor in the piglet area ensures their space remains exceptionally dry and waste-free. This physical separation helps control manure distribution and minimizes cross-contamination between the sow and her litter.

Every component is selected for durability and cleanability.

The FRP (Fiber Reinforced Plastic) beams offer superior strength and corrosion resistance compared to traditional steel, with a smooth surface that wipes clean effortlessly.

The PVC fences provide a robust, non-porous barrier that is impervious to moisture and chemicals, allowing for complete disinfection.

Integrated sow trough and piglet feeder are designed with smooth contours and no internal corners to prevent feed residue buildup and microbial growth.

A key to disease resistance is reducing stress and supporting robust health from birth.

The dedicated heating cover over the piglet zone provides a critical, localized warm micro-climate. This prevents chilling stress, conserves the piglets' energy for growth and immune function, and draws them away from the sow's area, reducing crushing risk.

The combination of solid and slatted flooring by zone ensures optimal thermal and physical comfort for both sow and piglets, promoting overall welfare and resilience.

This entire system is built for the rigors of modern batch farming. The modular design allows for quick assembly, disassembly, and thorough cleaning between farrowing groups. When the crate is empty, every component—from the FRP beams to the PVC panels—can be accessed, power-washed, and disinfected, leaving zero organic matter behind to break the disease cycle.

A 500-sow integrated farm in Southeast Asia was struggling with persistent health issues and inefficient cleaning in their old, worn concrete pens, despite strict perimeter ASF controls.

The Upgrade: They conducted a trial, installing MHFarming's BMC slatted floors in gestation areas for ultimate durability, plastic slatted floors in farrowing rooms for optimal hygiene and rapid drying, and triangular steel floors in heavy-duty finishing pens. The farrowing rooms were equipped with our zoned farrowing crates featuring piglet heating covers, PVC fences, and FRP beams.

The Result (Measured after 6 months):

Pen surface drying time: Reduced by over 65%.

Water and labor time for thorough cleaning: Decreased by an estimated 35%.

Airborne ammonia levels: Notably improved.

Piglet pre-weaning mortality: Saw a measurable reduction.

Operational Insight: The farm manager reported: "The different floors and crates gave us targeted solutions. Most importantly, we now have a system we can clean and dry completely. It's the foundation our biosecurity protocol was missing."

ASF defense is a layered system. While keeping the virus out is priority #1, preparing the internal environment to minimize its impact if it breaches the perimeter is equally vital. Modern, strategically chosen slatted floors and intelligently designed pens form a passive yet powerful defensive layer—they actively create a cleaner, drier, less stressful, and more manageable environment where pathogens struggle to persist and spread.

Your housing system shouldn't be your weakest link. Let us help you make it your strongest asset.

Request a Free Farm Layout Review: Send us your pen layout. Our engineers will provide a free analysis and product recommendation.

Get a Tailored Quotation: Receive a detailed quote for a housing solution designed to mitigate your specific risks.

Contact us today to transform your housing into an active ASF barrier.